Sustainability

Environmental Protection

The RIKEN TECHNOS GROUP established our environmental policy and obtains ISO 14001 certification to establish ourselves as an enterprise that contributes to the realization of a prosperous society and responds to the trust of all its stakeholders through environmentally conscious corporate activities.

At the top is the executive officer overseeing the environmental system. Under the direction of the Chief Environmental Management Representative, we appoint environmental management representatives at each site, and build and operate our environmental management system.

Environmental Policy

For all our business activities, we take into consideration the effects on the environment. To protect the environment and realize a sustainable community, RIKEN TECHNOS CORPORATION established an environmental management system, and all members of RIKEN TECHNOS CORPORATION work to implement the following principles.

- Through all business activities, RIKEN TECHNOS CORPORATION improves the environmental management levels and the prevention of the environmental pollution by not only observing all environmental regulations and mutual agreements but also setting our own rules and regulations voluntarily.

- RIKEN TECHNOS CORPORATION supplies the market with various plastics that prioritize the environment such as those that are energy- saving, resource-saving, recyclable, and that have low-impact on biodiversities and ecological systems, while using guaranteed safe raw materials.

- RIKEN TECHNOS CORPORATION reduces its impact on the global- environmental, biodiversities and ecological systems by eliminating wastefulness wherever possible. We reduce industrial waste by using materials effectively, and CO2 discharge by making efforts to save energy.

- RIKEN TECHNOS CORPORATION continues environmental protection activities by establishing documents including the Environmental Policy, and by educating employees.

- RIKEN TECHNOS CORPORATION sets concrete objectives and numerical targets of which progress is regularly self-assessed and managed properly to ensure the achievement of the Environmental Policy.

- RIKEN TECHNOS CORPORATION implements the above-mentioned activities Group-wide to ensure the utmost consideration to the protection of the environment, biodiversities and ecological systems and the safe operation at each site.

- RIKEN TECHNOS CORPORATION aims to obtain confidence and understanding from society through appropriate and accurate information disclosure.

Certification of ISO 14001: 2015

Registration date: October 31, 2001(certification being maintained)

Certification scope: 100%(non-consolidated)

Environmentally Friendly Products

In addition to complying with various laws and regulations on the environment and chemical substances, our Group carries out environmental management at a high level-such as reducing the use of chemical substances with high environmental load and using solar power generation-and work on developing products and improving manufacturing methods aimed at reducing environmental load. We also state “Contribute to solving environmental and social issues” as one of the strategies in our three-year medium-term business plan, and strive to expand sales of the biomass plastic product RIKEBIO®, environmentally friendly materials such as rubber and paint substitutes, and polyvinyl chloride (PVC) and thermoplastic elastomer (TPE) products. In FY2023, we reinforced the RIKEBIO® series, started selling RIKEN WRAP BOTANICAL, and developed and launched reform materials for recycled rigid polyvinyl chloride (PVC).

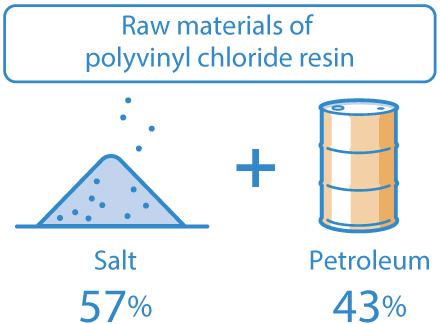

PVC can be said to be a material that has less environmental impact than other general-purpose resins made from 100% petroleum derived raw materials because salt (a natural material) accounts for about 60% of its raw material. PVC products can be given various functions, such as long life spans, durability, and recyclability. Furthermore, using biomass plasticizers, we seek to reduce environmental load by developing compounds and films that are blended with plant- and nature-derived additives.

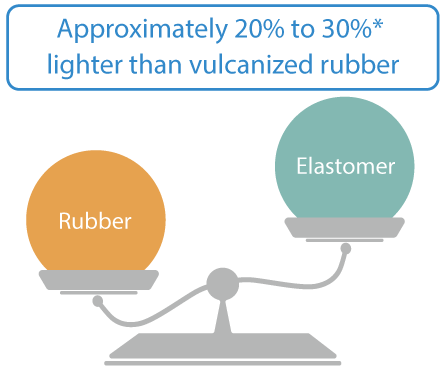

TPE has the same elasticity as rubber at room temperature and can be freely molded when heated. It can be molded with less energy than vulcanized rubber, which requires heat and time for function onset, and material recycling is also possible. We are developing high-functionality products by adding functions as necessary for the required application. In addition, it is lower relative density compared to vulcanized rubber, helping to make automotive components lighter and improving fuel efficiency, thereby contributing toward saving energy.

■ PVC products with high durability and long life spans

Compared to other resin products, PVC products have long life spans and can be used for ten years to several decades in construction applications, thereby helping to save resources. They have a wide range of applications as they can be used both indoors and outdoors.

■ Elastomers that are useful as rubber substitutes

Widely used in molded component for automobiles such as sealing materials, elastomers also contribute toward making vehicles lighter and improving fuel efficiency. In addition, as they do not require a vulcanization process, they can also be used in medical products that require a high level of hygiene.