Sustainability

Safety

Safety and Health Activities

Concept of Safety and Health Activities

Based on respect for people, RIKEN TECHNOS CORPORATION considers occupational health and safety to be one of the most important foundations in business operations, and strives to maintain and improve a healthy and safe working environment. We carry out our business operations with an occupational safety management system in accordance with ISO 45001.

Eradication of Causes of Dangers and Hazards through“ Risk Assessments”

Following the introduction of risk assessments (RA) in 2003, improvement activities to prevent incidents were established to eliminate and separate potential dangers and hazards in the workplace to reduce risks. Going beyond “zero industrial accidents,” all employees work to achieve “zero risks” by participating in safety awareness and risks and systems improvement activities.

-

Danger experience education (falling/dropping from heights) at Mie Factory Danger experience education was introduced to show in detail dangers that exist at the workplace and allow intuitive understanding of dangers in one’s immediate vicinity. Unlike learning knowledge in classrooms, such as education at workplaces, we think it is possible to supplement the lack of operator experience at the frontlines of work and contribute toward improving each individual’s safety awareness by learning safety and hygiene as experiences instead of concepts. -

Virtual reality safety education at Saitama Factory Educational contents making use of virtual reality were introduced as part of safety education and KYT (hazard prediction training) activities at the work site involved in dangerous work within the factory. By using virtual reality, operators can experience simulated industrial accidents and dangerous situations, helping to prevent accidents and improve safety awareness. -

Activities at RIKEN ELASTOMERS (THAILAND) CO., LTD. -

Activities at RIKEN VIETNAM CO., LTD.

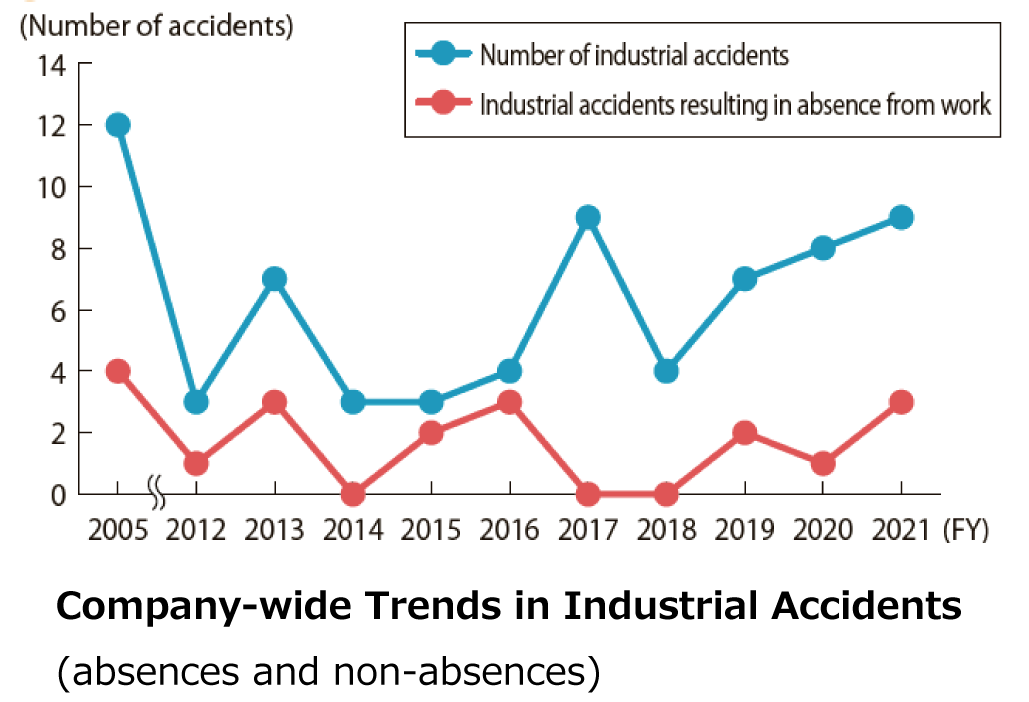

Number of industrial accidents

Review of Activities

In FY2021, our activities continued to focus on reducing industrial accidents to zero with RA promotion, promotion of the “pointing and calling” procedure, sharing and reviewing causes of past industrial accident information, eradication of unsafe behavior and unsafe conditions, and re-education of safety and health basics through self-prepared industrial accident prevention videos. Furthermore, making use of the remote working environment, we embarked on full-scale implementation of the online KYT and strove to improve the understanding and awareness of managers as well as operators. However, there were a total of nine industrial accidents: three resulting in absence from work and six that did not result in absence. Looking at the causes, many accidents were caused by bad position, posture, or method. It is clear that we need to enhance safety measures against unsafe acts during work. Going forward, we will enhance the contents of our education for operators using online KYT—implemented since FY2021—and our industrial accident eradication newsletter that is disseminated every month. In addition, we will also advance cause analysis from a human error perspective for operators and focus on activities toward reducing industrial accidents to zero by conducting risk assessment not only from the aspect of equipment but also the hidden risks in work.